Leaks in gas and water distribution networks are a significant problem worldwide, with economic, environmental, and safety implications. It is estimated that millions of kilometers of gas and water pipelines worldwide are characterized by ageing infrastructure.

Analyzing data from Italgas, Italy’s main distributor, it is estimated that, in the gas sector, on a network of more than 265,000 km, leaks occur at an average rate of about one every 2 km, causing massive waste and increasing the risk of accidents – including serious ones, up to and including explosions – requiring rapid intervention and sustainable repair solutions.

In terms of water losses, estimates indicate that more than 40% of distributed water is lost due to poorly maintained pipes. The problem is even more pronounced in towns in central and southern Italy, where losses can exceed 50%.

The state of the infrastructure poses a particularly critical challenge to the management of these networks in the face of an ever-increasing demand. Indeed, the global gas and water pipeline repair market is booming due to the increased need to maintain and modernize old and vulnerable infrastructure. In the case of water pipelines, the global repair market, which was worth about $72 billion in 2022, is expected to reach $121 billion by 2032, with an average annual growth rate (CAGR) of 6%.

Gas pipelines leaks are another global challenge, with a growing market due to increasing demand for natural gas and distribution networks that often require advanced technologies to reduce repair time and improve safety. The global gas leakage market has an estimated total value of $20.48 billion in 2023 and is expected to reach $27.90 billion by 2030.

This is the context in which Composite Research Srl (CoRe), an innovative Italian SME based in Turin, Italy, operates, specializing in the development and commercialization of advanced products based on composite materials. Composite materials, by their very nature, have endless applications: just think of wood, which is a natural composite material. A realization that led to the establishment of the company in 2015, with the aim of revolutionizing various industries through proprietary technological solutions based on composite materials that are light, strong and adaptable to specific applications. The mission is to integrate sustainability and innovation, improving the efficiency of production processes with reduced environmental impact. The business model includes engineering consulting, materials research, prototyping and manufacturing with a focus on high-tech industries.

CoRe’s expansion potential is significant: strengthened by a partnership with the Italgas Group, the company plans to expand their business to the European (and later the U.S.) market, extending the application of its technologies to new areas, such as hydrogen, drinking water, and high-tech sectors such as aerospace and automotive.

In the field of repairing damaged gas networks, and particularly in the low and medium pressure gas pipeline repair market, Madflex® technology emerges as a fast and cost-effective solution that can reduce the intervention time to as little as ten minutes and allow the repair to be carried out without service interruption.

CoRe holds an international patent portfolio that protects its innovations in composite materials. Madflex® technology is patented in Italy, Europe and the United States, and the company has additional intellectual property for other composite-based applications. The company adopts a hybrid development strategy based on “technology push” and “market pull,” combining technological innovation with market needs, often working directly with customers to develop solutions tailored to their specific problems.

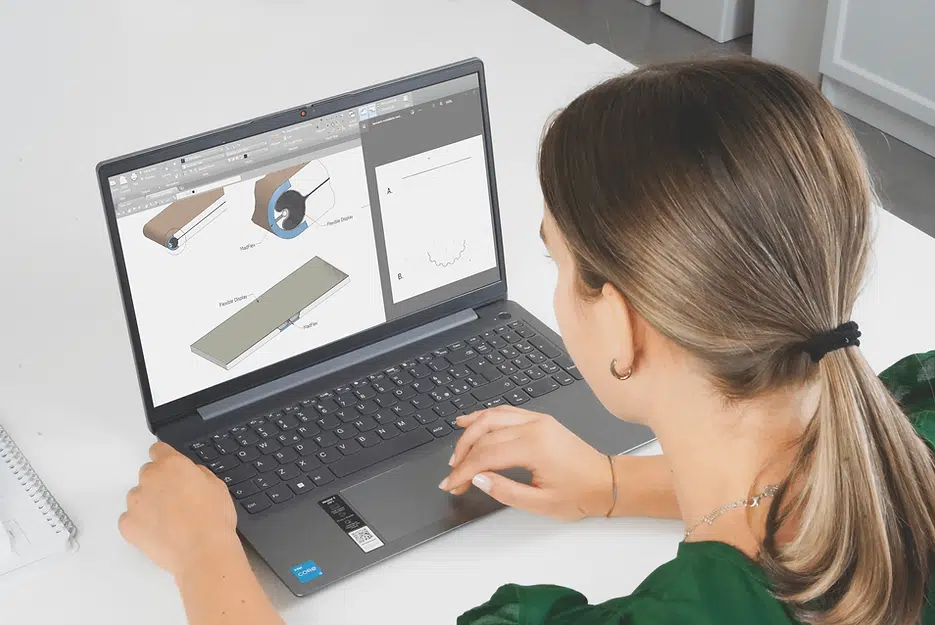

The main product developed by CoRe is the Madflex® Patch, an innovative solution for methane gas pipeline repair: it is based on a sandwich-like composite panel with asymmetric flexural characteristics. On the one hand, the panel behaves as a rigid and strong material (“MADly strong”), while on the other hand it can be easily rolled and bent (“super FLEX”). These features give the product a unique versatility, which enables it to solve pipeline leakage problems quickly and efficiently.

The Madflex® Patch has already found an important commercial application with Italgas, the leading gas distributor in Italy, which has signed a commercial contract for the purchase of thousands of repair kits for gas distribution networks. Not only does this strategic partnership confirm the technological validity of the product but also guarantees stable revenues for CoRe in the near future.

In addition, CoRe is developing a number of other applications based on composite materials. These include the Madflex® Hydro Patch, designed to repair leaks in water networks, and advanced materials such as Relight, which could replace more traditional materials such as fiberglass and carbon in sectors such as automotive and sports.

CoRe has also adopted a strategy of production internalization, with the aim of reducing the costs deriving from the outsourcing of some production steps. Thanks to the recent capital increase and a non-dilutive source of financing, the company aims to internalize the cutting and packaging operations of its products, consequently improving profit margins (as well as ensuing greater control over product compliance).

During the first quarter of 2024, CoRe launched a financing round with the goal of raising 1 million euros. This capital will be used to expand the business at an international level, strengthen the sales team and further develop the intellectual property through new patents and innovations.

The transaction was supported by LIFTT, which closely monitored the company’s evolution in recent years before deciding to invest in it directly and sees the technological viability of its products and its emerging customer base as the first signs of the growth it has promised. The investment in Composite Research Srl (CoRe) represents a significant opportunity in the field of composite technologies based, which are gaining ground in multiple sectors.

Exit prospects include acquisition by companies in the chemical and composite materials sectors, which have been particularly focused in recent years on creating an increasingly diversified product pipeline, or in the energy distribution and maintenance sectors. Another possibility is represented by the interest shown by private equity funds, which are attracted by the potential for business expansion.